Lower densities of packed straw and clay have been used in Europe for centuries, to fill in the gaps in half-timbered, and or wattle and daub construction. This is the lineage from which the modern light earth method evolved.

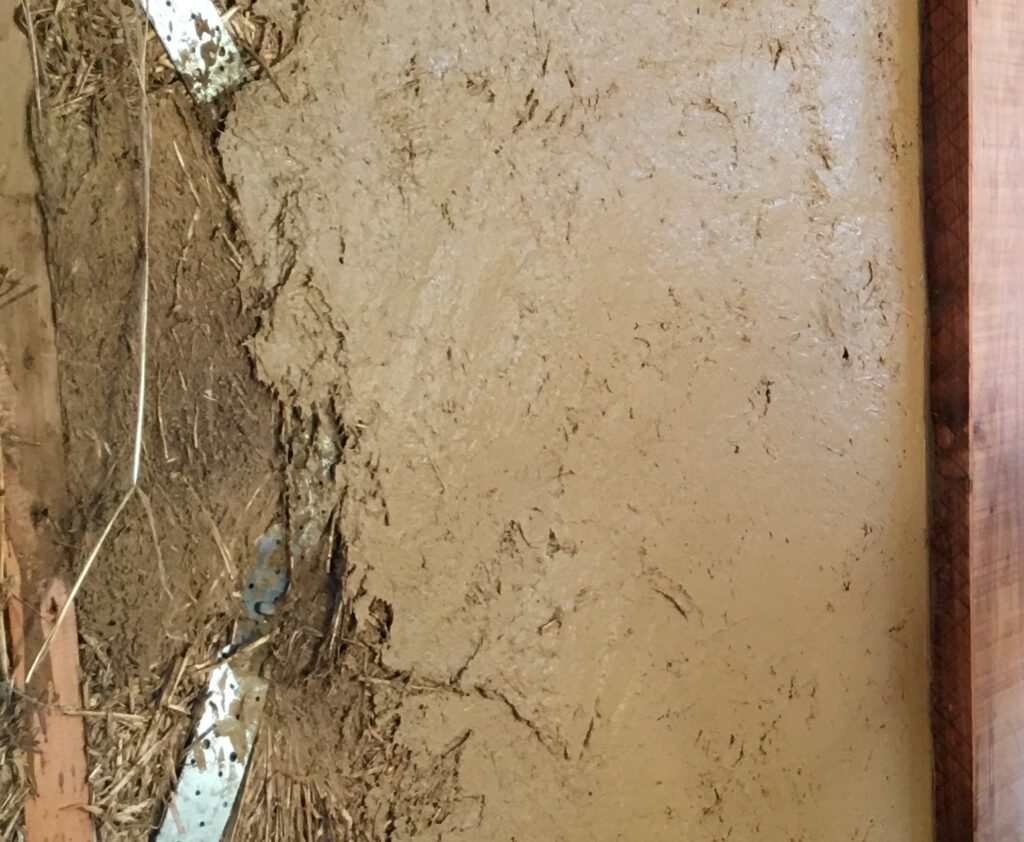

LEM or light earth method, is an ‘infill’ technique, and as such it does not hold up the roof. It may however, be thought of as ‘semi structural insulation’, taking wind and earthquake face loads i.e. a moist mix is tamped inside a structural frame, but it may have render or plaster directly applied to it. It consists of a natural fibre, or lightweight mineral, coated in a ‘clay slip’ binder, and usually placed inside temporary formwork. This temporary formwork or shuttering, will span between the structural wall framing members.

As the walls are typically quite thick, up to a maximum of 300 mm, rather good insulation levels can be achieved. It should be noted, that the insulation potential depends on how heavily the material is tamped into the shuttering, and the proportion of clay to fibre i.e. the density.

In addition to the insulation, these walls also have thermal mass potential. If designed well, to harness the benefits of passive solar, LEM walls will promote much higher internal thermal comfort levels, than would be achieved with other walls of equivalent insulation, but lacking thermal mass qualities.

As it is a ‘wet’ construction technique, the walls will shrink as they dry, and the builder will have to factor the drying period into their build schedule. This may take considerable time, and it is suggested that the LEM is installed right at the start of summer, for the best drying conditions.

Usually, clay plasters will be applied to the internal faces of the LEM, and this will add to the thermal mass and humidity buffering qualities of the walls. Externally, the walls may be clad, have a rain-screen applied, or be lime rendered, in accordance with the risk matrix in the revised earth building standards.

As a potential bio-based building method, fibre based LEM structures may be carbon sequestering. This is far better for the environment than conventional ‘green’ construction. Many conventional ‘green’, or ‘sustainable’ building methods, aspire to achieve operational ‘net zero energy’ at best. This means they produce (or use) as much renewable energy as they consume. Whilst a noble goal, this ignores the more immediate problem of embodied energy. It is like fighting a battle with one hand tied behind your back, i.e. building structures that are ‘net zero energy consumption’, but building them out of high energy materials such as steel and concrete, could send the world over dangerous tipping points by the very action of building them alone. In addition to ‘net zero’ operational energy, we really need to build with bio-based, carbon sequestering materials. This will allow us to fight climate change with both hands free, to reduce, and help rectify the negative climate effects of the construction industry.

There is an informative Appendix in 4299:2020 on LEM, to help guide those designing, building, or approving work with this technique.